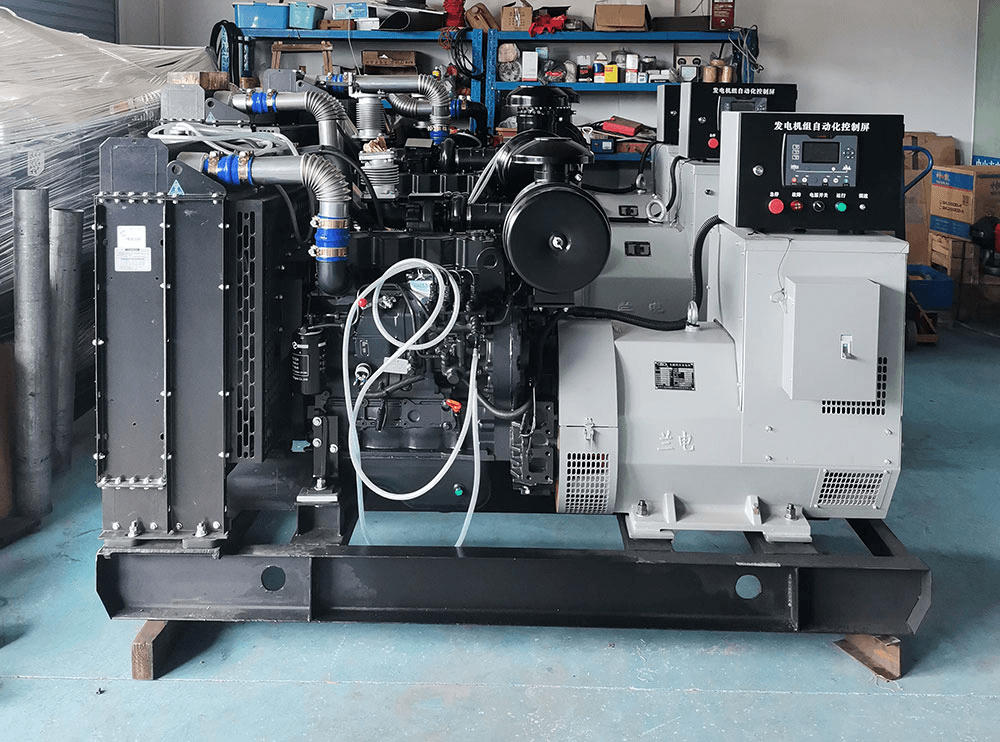

Observation units and surrounding the diesel generator set, which make sure the the device run in the safe environment.

1. Observation units and surroundings are there any debris. If you have to remove it in time to avoid inhaling the machine or wrapped the belt, it may even damage the machine or debris to fly out of the injury or equipment.

2. Check whether the water tank water level meets the boot requirements and whether there is water leakage, and then check whether the diesel label meets the requirements and whether there is oil leakage. Whether the total switch of the generator set is in the position.

3. Prepare the upper and negative electrodes of the battery line, and then observe whether it starts normally.

4. After starting, observe whether the oil pressure is normal, and generally stipulates between 0.4-0.6MPa.

5. Start up to run for three minutes, and then increase the throttle to the rated speed of 1500 rpm. After three minutes, observe whether the oil pressure, water temperature, oil temperature, voltage, and frequency are within the normal range. After starting, pay attention to the oil pressure. Diesel engines are prohibited from accelerating when the oil pressure is not rising.

6. The diesel engine should not be powered immediately after starting. When the oil temperature is higher than 45 degrees Celsius and the water temperature is higher than 55 degrees Celsius, it can gradually enter the full load operation, otherwise the cylinder that is easy to pull the cylinder will crack.

7. Start sending electricity after observation. Power delivery should be separated first. Determine whether the line is normal. After normal, the gate is closed, and the observation voltage is 400V, whether the frequency is 50Hz, and whether the current is within the rated range. The temperature of the oil pressure water is normal, and the entire operation program is completed.

8. Check the cooling water, fuel, and oil of the diesel engine before starting. Check the oil surface of the oil bottom shell and fuel injection pump. Whether the cooling water reaches the top surface of the water room, no leakage should be available in all parts. The inspection unit has oil leakage, water leakage, and air leakage.

9. Check whether the oil bottom shell oil is “full”. If necessary, it is necessary to make up the oil. If the oil is dirty, there is no viscosity, and fresh engine oil needs to be replaced. In winter, you need to replace the corresponding low temperature oil according to the environmental temperature.

10. Water cooling units check whether the water tank coolant is filled. In winter, the corresponding antifreeze needs to be added. Pay attention to the freezing of cooling water when using it. After stopping, you should unscrew the aircraft, pump pumps, oil coolers, and water discharge valves on the heat sink to exhaust the cooling water.

11. Check the fuel position of the fuel tank. If there is no fuel, it should be injected in time. Pay attention to often cleaning the fuel tank to keep the fuel clean.

12. Check whether the battery voltage is normal. If the voltage is low, it should be charged in time.

13. Check whether the wiring of the unit is loose.

14. Automated units need to do the above work frequently to keep the crew running normally in time.

Post time: Feb-18-2023